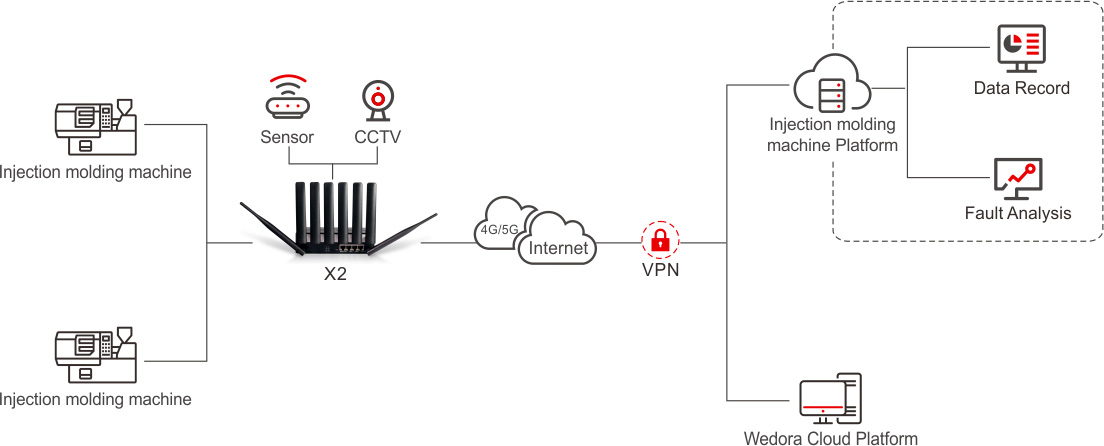

With the continuous upgrading of the manufacturing industry, traditional manufacturing is developing towards intelligent manufacturing. Equipment networking, informatization, and intelligent management are issues that manufacturing enterprises urgently need to solve. Injection molding machine manufacturers are facing the challenge of industrial transformation. The automotive, construction, household appliances, medical and other industries have increasing demand for injection molded products, with the market for injection molding machines is constantly expanding, the "energy saving, environmental protection, high precision, automation, networking" has also become an increasingly obvious trend. Based on industrial experience, Hongdian provides a complete set of solutions to help customers land faster and make the injection molding machine become intelligent and energy saving.